bloques info producto

Bank Transfer (3% OFF)

If you make the payment via bank transfer, you will receive an extra 3% discount on your order.

Need to upgrade your equipment?

Would you be interested in trading in a device when purchasing this item?

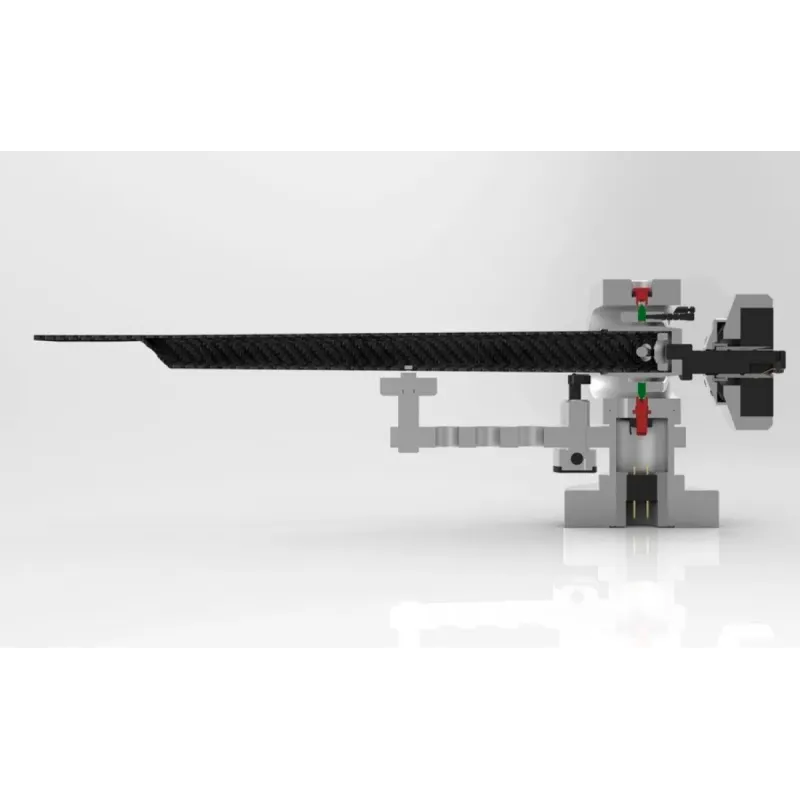

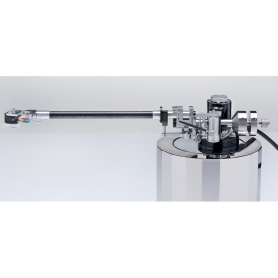

If you look closely, you can see that the arm tube is conically shaped, which means its diameter narrows towards the cartridge and the headshell. This design prevents reflections of standing waves. The arm tube is secured by a single screw that allows easy azimuth adjustment. The internal wiring is made of flexible, high-purity copper, an excellent conductor for low-level phono signals. Each wire is equipped with a gold-plated cartridge connector clip.

Arm Bearing

The arm pivots on an inverted gimbal bearing of ABEC 7 quality with 4 stainless steel tips. This type of bearing is very stable and low friction, ensuring clean tracking. This results in a detailed and open soundstage where all the micro-information of the record's groove is preserved. The bearing is housed in an all-aluminum casing that provides necessary stability. The large outer ring of the gimbal is open to prevent bell mode resonance. Due to the arm's design, the bearing requires no maintenance but is very easy to adjust if necessary.

Tracking Force and VTA Adjustment

We supply two counterweights with each arm for broad cartridge compatibility from the outset. The counterweights themselves are more than they appear. They are damped by TPE, significantly aiding in resonance control. Always use the counterweight that can be placed closest to the pivot point with the desired tracking force applied. This ensures maximum stability and keeps arm inertia as low as possible.

The arm height can be continuously adjusted by loosening and retightening the two set screws on the arm base. This allows the arm to be perfectly adjusted to your VTA requirements. Experimenting with VTA and azimuth is crucial for extracting every last bit of performance from your phono cartridges.

An overview of Pro-Ject's arm design philosophy.

The arm is one of the most critical parts of a turntable and can have a significant impact on the overall sound quality. That's why we conducted in-depth listening tests with various types of bearings, arm materials, and cartridge combinations to achieve the sound quality we were aiming for. About 15 years ago, we designed and launched the revolutionary EVO CC arm range in 9", 10", and 12" lengths with one-piece carbon fiber tubes. They were a great success and drove us forward in our research and testing, leading to our latest and greatest arms. The EVO and EVO Premium arm ranges are the culmination of our work, and we are proud to offer them in new finishes and with many additional enhancements.

Key Insights from Our Research and Development

Pro-Ject has been designing arms for over three decades. We've tested numerous arms both by ear and performance measurement with nearly 50 cartridges from across the market. Our research conclusively led us to these ten key insights...

Damped counterweights and gimbal bearings with high-mass dampen arm resonance.

A one-piece arm tube increases rigidity while reducing mass at the arm end, enhancing transparency.

Low-compliance cartridges perform better on arms with high effective mass.

A high-mass (arm) mounting plate is crucial to securely fix the arm to the plinth.

A variety of counterweights is optimal so the weight itself can be placed as close to the pivot as possible for increased stability and low arm inertia.

A conical arm tube ensures resonance is shifted towards the bearing block (away from the cartridge) and also reduces the moving mass of the arm/cartridge combo.

The right combination between arm and cartridge and resulting resonance between cartridge and arm are crucial for accurate tracking and controlled bass reproduction.

Good conductors have a significant and positive influence on low-level cartridge signals, so we use copper of the highest purity (EVO arms) and silver (EVO Premium arms) to carry the signal from your phono cartridge.

A solid, sturdy arm support actually reduces overall arm resonance.

A precision arm must be manufactured with the highest level of diamond blade machinery, allowing it to work within tolerances within 1/1000 of a millimeter.

We've designed the latest EVO arm series based on these technical insights. The central design concept is that a high-mass gimbal is used with a set of 4-point, low-friction bearings made in Switzerland. We've implemented the best 4-point gimbal bearings to ensure accurate tracking and expansive sound staging.

The EVO range is a complete family of arms. It allows you to select the ideal arm for your favorite cartridge or an arm that can accommodate a collection of cartridges. We offer lower mass arms (carbon fiber), slightly heavier carbon/aluminum arms, as well as higher mass S-shaped aluminum arms with bayonet-style universal headshells. Of course, replaceable headshells allow another world of adjustments. EVO arms are available in 9, 10, and 12-inch lengths, in standard finishes in black or hand-polished silver. Premium versions use an improved stainless steel bearing block design, silver-plated arm wiring, and an enhanced counterweight design, making it the most comprehensive arm range in the current market.

Considerations for Cartridge Resonance Frequency

When selecting a cartridge for your turntable, the total effective mass of the arm (effective mass of the arm and headshell + cartridge and hardware mass) in relation to the mechanical compliance (compliance) of the cartridge's cantilever system should be considered. A correct mechanical match between the cartridge and arm is one of the most important factors in achieving neutral sound. A mismatch can lead to poor impulse behavior (lower dynamic and microdynamic resolution, narrowed soundstage, bloated or thin bass). A resonance frequency between 7 and 12 Hz is optimal for any arm/cartridge system.

Overview of Turntable and Arm Compatibility

Compatibility between Pro-Ject turntables and EVO arms is straightforward. In summary, if your current or future turntable has a 9″ arm, any of these 9″ variants will work perfectly: EVO 9 CC (included), EVO 9 CA Premium, EVO 9 AS, EVO 9 AS Premium. If your current arm uses a balanced 5-pin DIN connector, the EVO arms come out the same way and are direct replacements (no soldering required!). If your current arm terminates in a junction box with RCA outputs, soldering will be necessary. For DIY enthusiasts who can perform the advanced work required to properly install an arm on an external plinth, EVO arms are mounted according to the Linn standard and come with mounting templates. Here's a quick summary of arm length compatibility with our current turntables:

9-inch arms

Xtension 9, X8 Evolution, RPM 9 Carbon, 6PerspeX*, X2 B*, RPM 5 Carbon*, The Classic EVO* (*soldering required)

10-inch arms

Xtension 10, RPM 10 Carbon

12-inch arms

Xtension 12

Do not order an arm with a length that is incompatible with your plinth. For example, if you mount a 10″ arm on a platform designed for a 9″ arm, you won't be able to align your phono cartridge correctly. Also note that Signature 10 and 12 arms are not interchangeable with the EVO range.

ADDITIONAL INFORMATION

Length

9", 10", 12"

Finish

Black, high gloss

Features:

Flexible high-purity copper internal wiring.

Aluminum bearing block

4-point low-friction gimbal arm bearing

Rigid and lightweight carbon tube

Counterweight damped by TPE

Precise azimuth and VTA adjustment

Outer gimbal ring is open to prevent bell mode resonance

Arm lift with silicone damping can be adjusted to suit arm height

Gold-plated 5-pin DIN output socket

Hand-polished silver aluminum parts.

Available in CC Black and CC HG versions in 9, 10, or 12 ″

Made in Europe

Specifications (12 / 10 / 9")

Effective arm length: 304.8 / 254 / 230 mm

Mounting distance: 291.6 / 238 / 212 mm

Offset angle: 18 / 21.4 / 24°

Overhang: 13.2 / 16 / 18 mm

Mounting slot pitch of headshell: 12.7 mm

Effective arm mass: 10.5 / 8.5 / 8 g

Cartridge weight: 6-15 / 6-14 / 7-14g

Tracking force range: 0-3g

Minimum pivot to spindle distance: 125 / 126.8 / 130.6 mm

Maximum pivot to spindle distance: 251.7 / 248.2 / 243.7 mm

Arm weight: 271 / 269 / 265 g